Japanese electronics company Toshiba has developed a new kind of cobalt-free battery that could lead to cheaper, more sustainable EVs in the future.

The challenge: Road transportation is a significant contributor to climate change, accounting for 12% of global greenhouse gas emissions, so transitioning from fossil fuel-powered cars and trucks to electric vehicles (EVs) is crucial to meeting our climate goals.

The lithium-ion batteries used in most of today’s EVs have several problems, though, and a big one is that their cathodes are made of cobalt, a rare and expensive metal often mined using child labor and environmentally destructive practices.

While some EV makers, including Tesla, do use batteries with cathodes made of a different material — called “lithium iron phosphate” (LFP) — those batteries tend to charge more slowly and have lower energy densities, meaning range takes a hit.

Cobalt is a rare and expensive metal often mined using child labor.

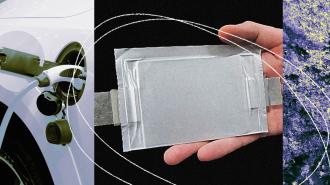

What’s new? Toshiba has now developed a new type of cobalt-free battery. Its cathode is made of a material called “nickel manganese oxide” (LNMO), while its anode (a component usually made of graphite) is made of “niobium-titanium oxide” (NTO).

Toshiba says the use of these materials makes the battery a “superior solution in terms of cost and resource conservation” compared to batteries containing cobalt.

Testing the tech: In testing, a prototype of the cobalt-free battery could be charged to 80% capacity in just 5 minutes — according to Toshiba, an LFP battery cell needed 20 minutes to hit that milestone.

The new battery was also more durable than the LFP cell that Toshiba tested — it could maintain at least 80% of its original capacity after 6,000 charge/discharge cycles, while the LFP cell could only handle 3,000 cycles.

Looking ahead: Toshiba’s cobalt-free battery is still in the early stages of development, and a lot about the device is still unknown, including how its energy density compares to that of LFP and traditional lithium-ion batteries.

A prototype of the cobalt-free battery could be charged to 80% capacity in just 5 minutes.

Still, Toshiba sees promise in the tech and is hopeful it’ll be ready for commercialization by 2028. The company’s plan is to start small, with batteries for power tools, before eventually scaling up to EVs.

“To make the battery bigger, deep verification processes are still needed, and we believe we should start from areas with lower technical barriers and then target automotive applications with higher technical barriers,” principal researcher Yasuhiro Harada told EV Riders.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].