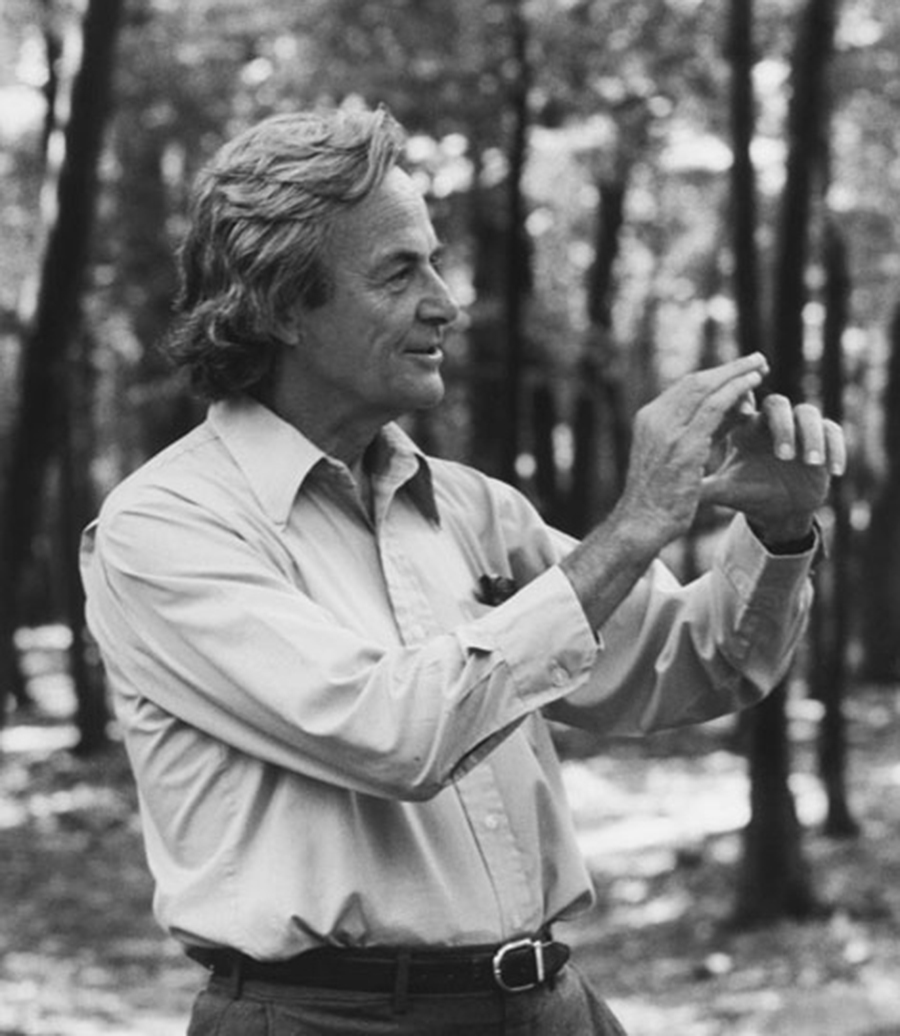

At a 1959 meeting of the American Physical Society at Caltech, physicist and Nobel laureate Richard Feynman gave a talk titled “There’s Plenty of Room at the Bottom,” which opened with a simple question: “Why can’t we write the entire 24 volumes of the Encyclopedia Britannica on the head of a pin?” His answer — we can, if we construct machines capable of performing molecule-sized tasks – was, at that point, more science fiction than science. Still, Feynman managed to spark the imagination of his peers, kickstarting the development of a new field of research we now know as nanotechnology.

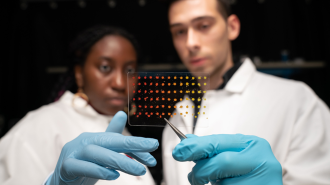

Today, nanotechnology can be defined as manipulating matter at a size of 1 to 100 nanometers. Considering that the tip of your average pin has a diameter of 235,000 nanometers, it’s safe to say nanotechnology has made tremendous strides since Feynman took to the stage in 1959. Nowadays, some of the most exciting developments in the field are happening at MIT.nano, a multidisciplinary research facility at the Massachusetts Institute of Technology that first opened its doors in 2018.

“One of the key advances we have made is the ability to image at the sub-atomic level using electron microscopes,” the lab’s associate director, Brian Anthony, tells Freethink after speaking at EmTech, a yearly conference on emerging technologies hosted on MIT’s Cambridge campus. Nanotechnology, he explains, is about more than making existing gadgets smaller. As any quantum physicist could tell you, the way matter behaves varies widely depending on how far the observer zooms in or out. This means that in order to develop, say, a device capable of delivering drugs to individual cells in our bodies, we first have to understand how things on such a microscopic scale actually work.

After decades of slow but steady progress, the research done at MIT.nano is picking up momentum. “We can now freeze matter in place and observe phenomena at that scale,” Anthony explains, “like atoms moving or dislocations forming.” In this interview, he dispels common misconceptions about nanotechnology and nanoscience, and reveals the huge contributions these deceptively small fields have made to civilization.

The world is constructed at the nanoscale, but because we are macro-scale beings, we tend to think on a macro-scale.

Big breakthroughs, tiny tech

The field of nanotechnology is, ironically, much bigger than people think it is. “The short answer is that ‘nano’ just means ‘small,’” says Anthony. “But to work at the nanoscale, you also need tools that control the environment at that scale: making sure the air is clean, reducing particle count, and keeping vibrations to a minimum.”

On the atomic and sub-topic level, even the slightest changes in temperature or moisture can profoundly alter the measurements extracted from an experiment, which is why MIT.nano’s labs are custom-built to give researchers as much control over their facilities as possible, allowing them to regulate everything from humidity to air filtration.

“Many ideas were overhyped or overlooked because we didn’t have an economically viable way to observe them.”

Brian Anthony

Another common misconception about nanotechnology is that it is exclusively about nanoparticles. “While some nanotech research involves nanoparticles,” says Anthony, “that’s not what MIT.nano is primarily about. We’re about providing the infrastructure to conduct research at the nanoscale in a variety of disciplines.” He stresses that nanotechnology research has big applications: “When you look at the strength of materials, it’s all built from the nanoscale. The world is constructed at the nanoscale, but because we are macro-scale beings, we tend to think on a macro-scale. Everything from Damascus steel to semiconductors involves nanotechnology.”

The same goes for photonics (the generation, detection, and manipulation of light). A variety of emerging technologies, from self-driving cars to smart glasses, require miniaturized optical systems that can transform one’s surroundings into usable data. On the research and development side, these kinds of systems can also be used to observe and study nanoparticles. “If you look at the history of microfluidics, or the behavior of fluids passing through micro-channels” notes Anthony, “many ideas were overhyped or overlooked because we didn’t have an economically viable way to observe them.”

Fortunately, this is no longer the case. Thanks to advances in integrated photonics, researchers now have the means to measure not just the size of many particles, but also their chemical makeup. According to Anthony, the upcoming challenge isn’t improving the sophistication of the sensors themselves, but finding a way for low-concentration particles to come into contact with those sensors.

One of the biggest developments in nanotechnology in the next five to ten years will be the opening of a “digital twin” semiconductor institute, which will enable microchip manufacturers to develop and test products virtually before they go into production. Largely funded by the federal government, the institute will hopefully not only boost the US domestic microchip industry, but also boost innovation in other fields like biotech, where researchers will likewise be able to run virtual tests at nanoscale before committing to actual, real-life experiments.

Bigger obstacles

One of the biggest obstacles in contemporary nanotechnology research is – unsurprisingly – the dual challenge of making devices both smaller and more sophisticated. “Traditionally,” says Anthony, “we have been able to miniaturize devices and connect them on circuit boards. Now, we need to put electrical, optical, and fluidic connections – all within a single package.”

Fortunately, funding for this kind of research is rising – partly because of geopolitical conflict. For decades, the global center of microchip manufacturing, a core part of the nanotech industry, has been based in Taiwan, an island nation which – according to Chinese leader Xi Jinping – is destined to be reunited, by force if necessary, with mainland China. As diplomatic relations between Taipei and Beijing have cooled, the US – Taiwan’s chief ally and trading partner – has started promoting initiatives to reshore the development and manufacturing of microchips, which in turn requires funding for nanotech research.

“Nanotechnology is often hidden behind walls, in labs or fabs … We try to get students into the fab during their freshman year.”

Brian Anthony

According to Anthony, legislation like the CHIPS Act – a 2022 bill that provides economic incentives for microchip manufacturers – have greatly accelerated the amount of funding available for micro and nano-scale technologies, even if federal dollars are but a small portion of total investment.

Another key obstacle to nanotechnology development worth considering is the availability of talent. Specifically, students. At MIT, the number of students studying nanotechnology has been increasing on a yearly basis – a phenomenon Anthony partly attributes to reduced interest in Big Tech and computer programming. “In the past, when you saw companies like Google and Amazon hiring programmers with high salaries, it’s easy to get pushed onto that path. Looking ahead, tools like AI may cause a shift. ChatGPT in particular could become a killer app for programming, helping non-programmers write code. While it still needs debugging, it can dramatically improve coding efficiency, which could reduce the demand for human programmers.”

As a result, “people might begin to look for other avenues where hands-on skills can be applied. Manufacturing – whether at the nanoscale or macro scale – could be a natural avenue for that.” He adds that, at MIT, students are not only showing higher levels of interests in nanotechnology but also in the physical sciences, which likewise require hands-on work that AI – for the time being – cannot replace.

Investment in introductory nanotechnology programs for high schools could drive up college enrollment further still. While many high schools offer courses or after-school programs that introduce their students to a large variety of scientific disciplines, including engineering and computer science, nanotechnology requires equipment and programming that the average secondary school simply cannot afford.

As a result, concludes Anthony, “nanotechnology is often hidden behind walls, in labs or fabs, so it’s not something most high schoolers get to see or touch.” That’s why, at MIT, “we try to get students into the fab during their freshman year, so they have more time to explore and decide if it’s something they want to pursue.” MIT.nano’s building has been designed with this in mind, with large windows allowing students to see what’s happening inside, sparking their curiosity in much the same way that Feynman roused his peers.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].